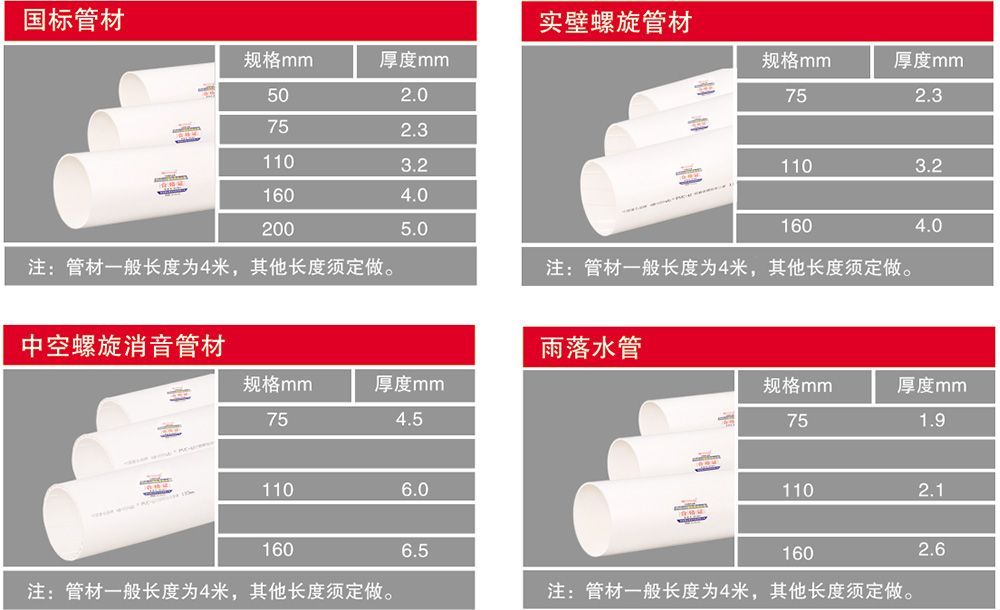

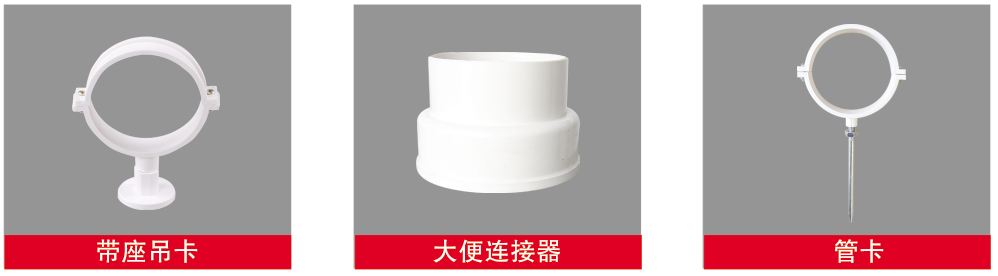

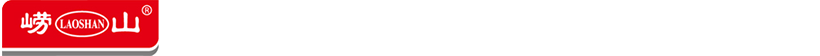

There are three types of products: straight pipe, flared pipe and flared pipe, which can be connected in various ways. In addition, the company has also developed pressure drainage pipes for rainwater drainage and beautiful square rain downpipes for design and engineering of rainwater drainage in different buildings; developed spiral silencer pipes, hollow spiral silencer pipes and hollow wall silencers that can reduce drainage noise Series drainage pipes such as pipes.

Features

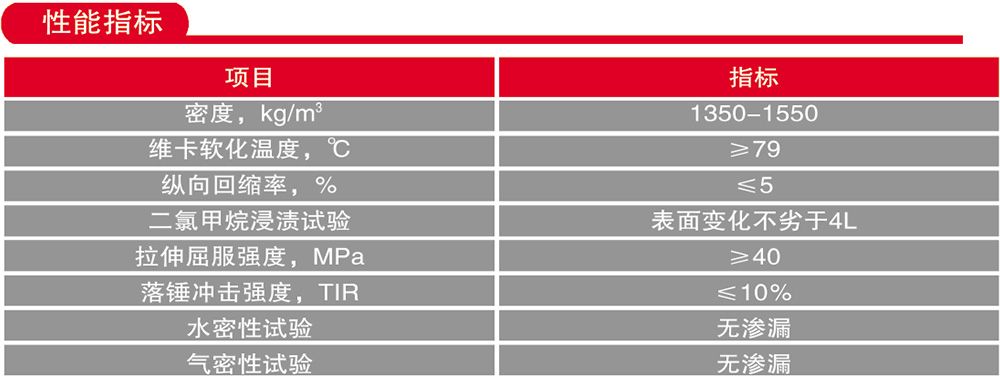

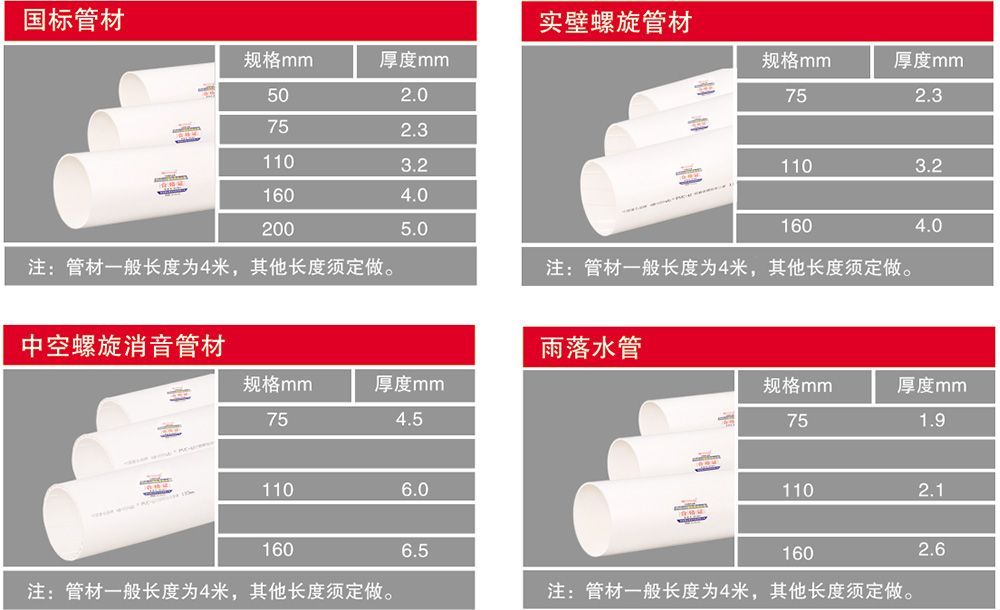

The surface hardness and tensile strength of the pipe are excellent, and the pipe safety factor is high.

Good aging resistance, normal service life can reach more than 50 years.

The pipeline has excellent corrosion resistance to inorganic acids, alkalis and salts, and is suitable for industrial sewage discharge and transportation.

The pipe friction coefficient is small, the water flow is smooth, not easy to be blocked, and the maintenance workload is small.

The material has a high oxygen index and is self-extinguishing.

The linear expansion coefficient of the pipeline is small, 0.07mm/m.℃, and the amount of deformation affected by temperature is small. The thermal conductivity and elastic modulus are small, and the frost resistance is better than that of cast iron drain pipes.

The pipes and pipe fittings can be connected by bonding, the construction method is simple, the operation is convenient, and the installation work efficiency is high.

In the indoor and outdoor drainage pipeline engineering of industrial and civil buildings, the temperature of continuous discharge of domestic sewage is not more than 40℃, and the temperature of instantaneous discharge of sewage is not more than 80℃; and industrial wastewater that does not corrode the pipes can be used.

Pipe connection

★Pipe socket connection should strictly follow the following procedures:

① Wipe clean the pipe sockets and pipe fitting sockets before bonding.

②Measure the depth of the socket and mark the pipe port.

③Apply the adhesive, first coat the socket and then the socket, the coating is even and appropriate.

④ Align the direction, insert into the marking position at a time, and rotate 1/4 turn.

⑤ Wipe off the remaining adhesive on the socket.

⑥ Let the bonded pipe stand still until the joint is cured.

★The safe use of adhesives should comply with the following regulations

① Adhesives and detergents should be opened and used immediately, and non-operators should not use them.

②There should be no open flame at the bonding point and good ventilation.

③It is not suitable for construction below -10℃, and the bonding points must not be baked with fire.

④ Construction personnel should be equipped with gloves. When the adhesive gets into the eyes, rinse immediately with plenty of water and send to the hospital for treatment.

Installation Notes

Saw pipe and bevel:

The length of the saw pipe is determined layer by layer according to actual measurement and combined with the size of each connecting pipe. Pipe sawing tools should be fine-tooth saws, cutters and pipe cutters. The fracture should be flat and there should be no deformation at the cross section. The part of the socket to be bonded can be filed into a 15°-30° bevel with a medium plate file. The groove length is generally not less than 3mm, and the groove thickness should be 1/3-1/2 of the pipe wall thickness. After the bevel is completed, the debris should be removed.

Protection of socket:

After connecting the socket interface, wipe the extruded adhesive with cotton yarn or dry cloth dipped in a little acetone and other cleaning agents. According to the performance of the adhesive and the weather conditions, let it sit until the interface is cured. The curing time during winter construction should be extended appropriately.